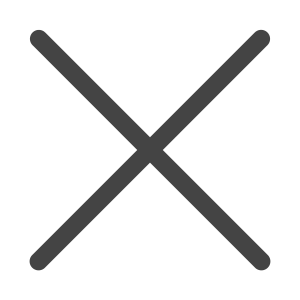

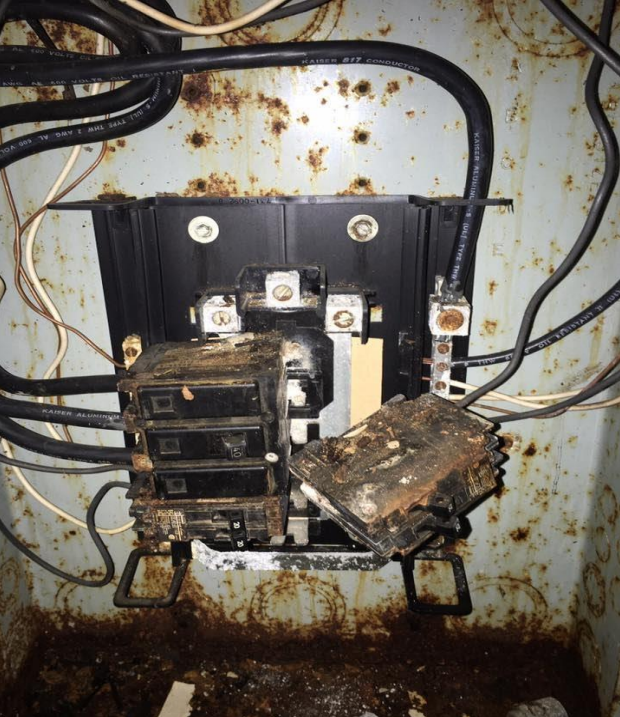

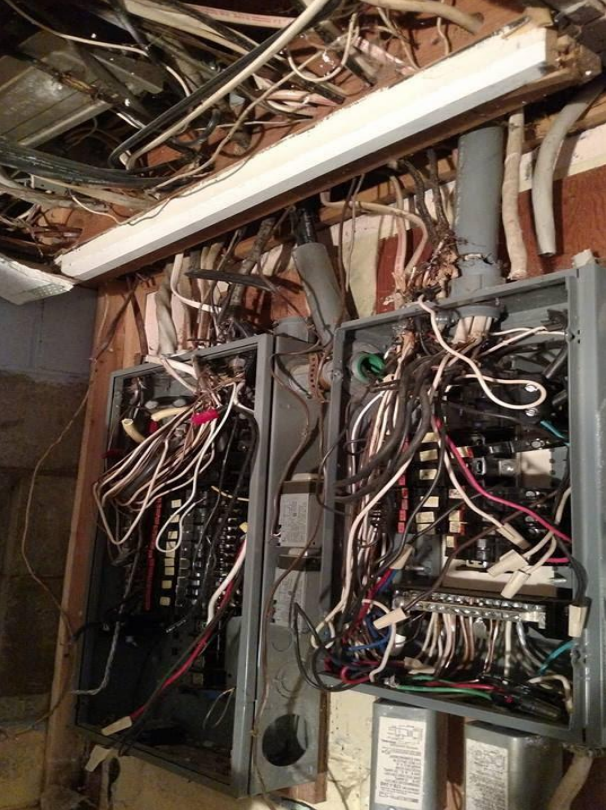

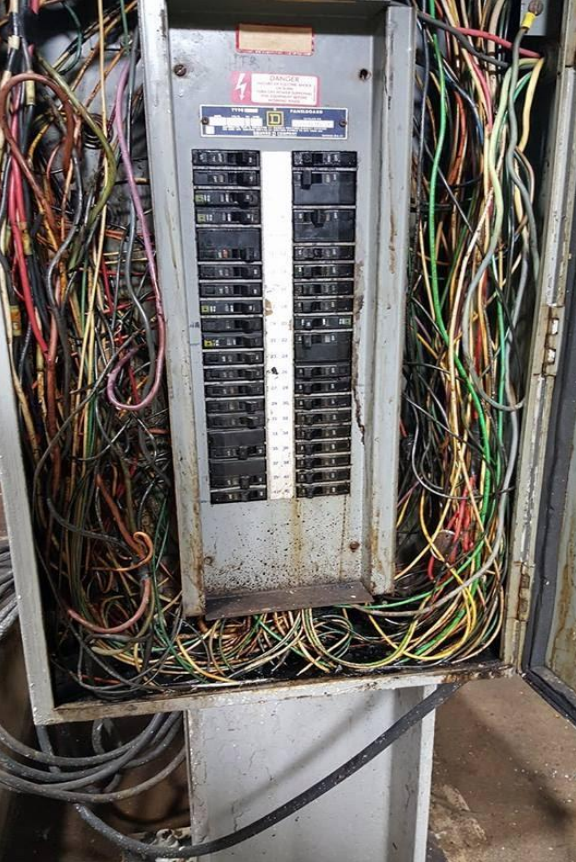

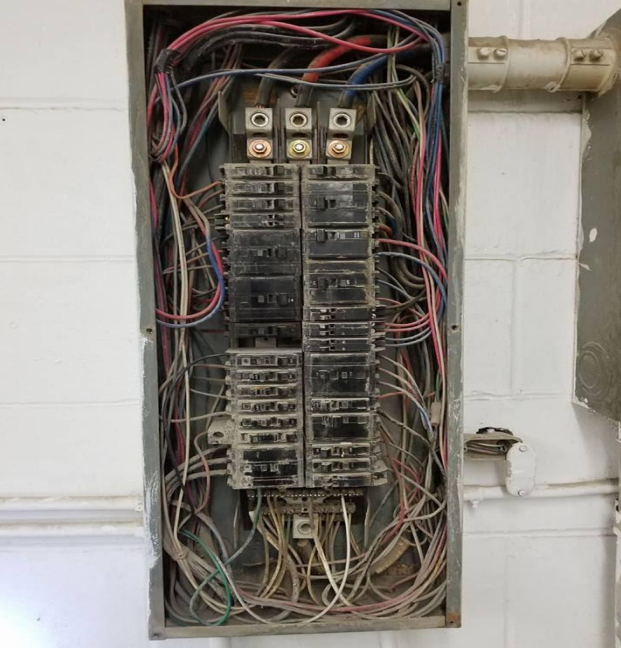

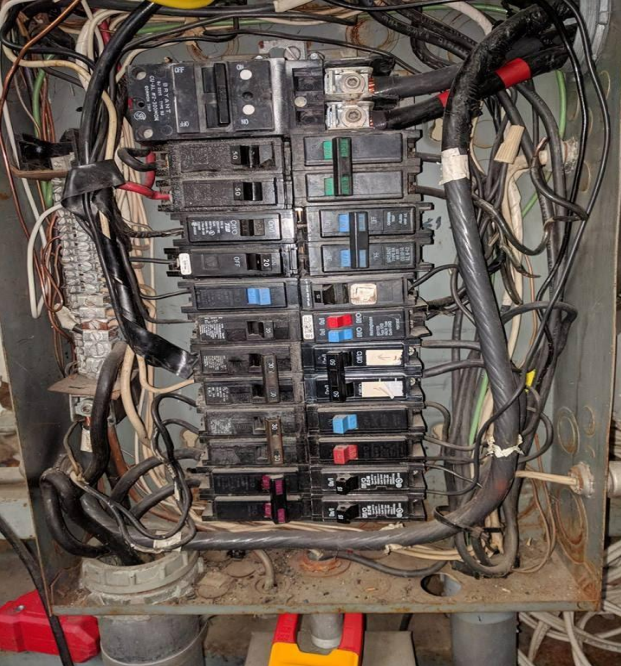

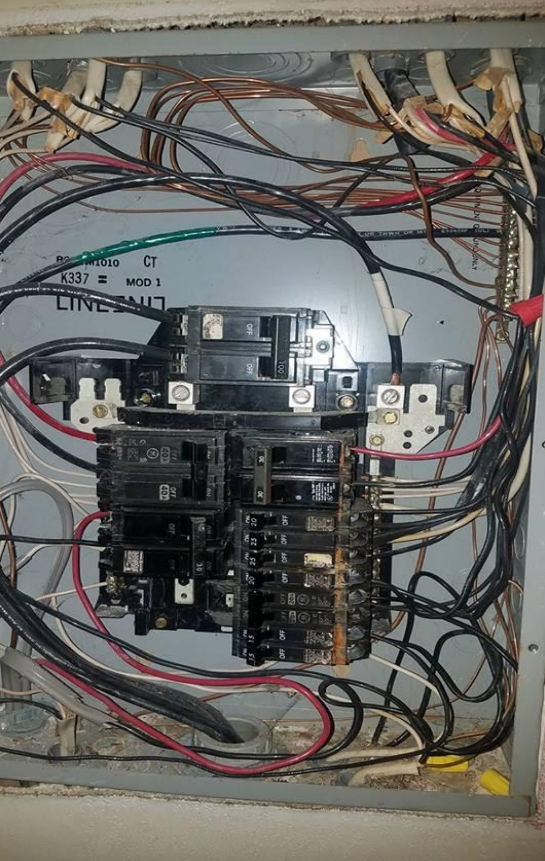

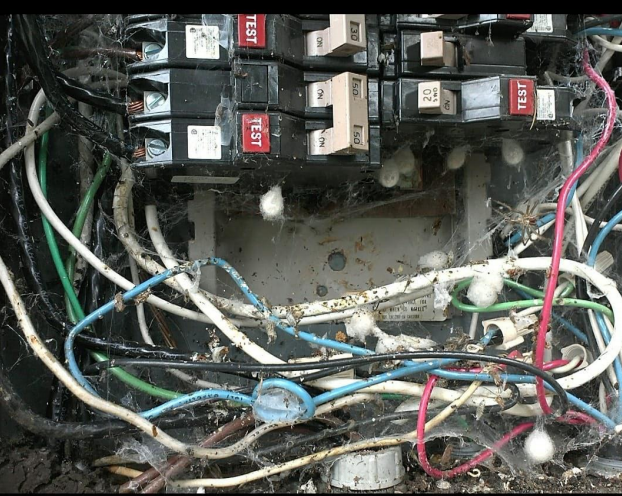

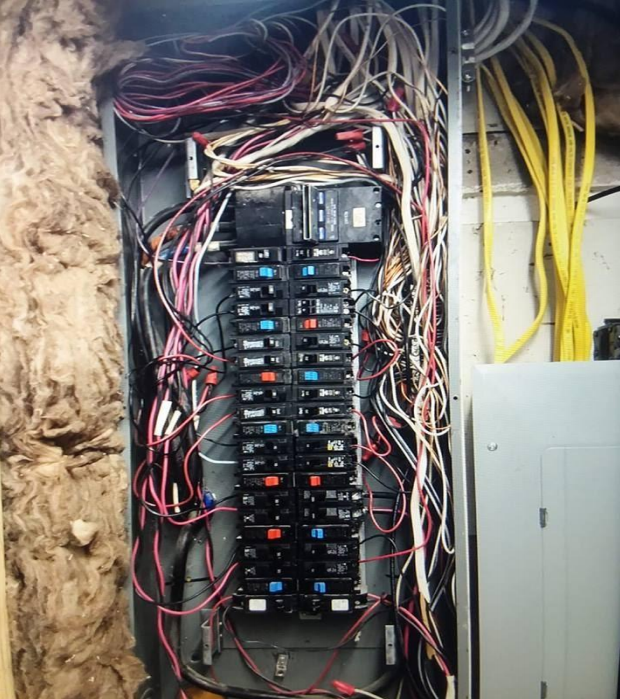

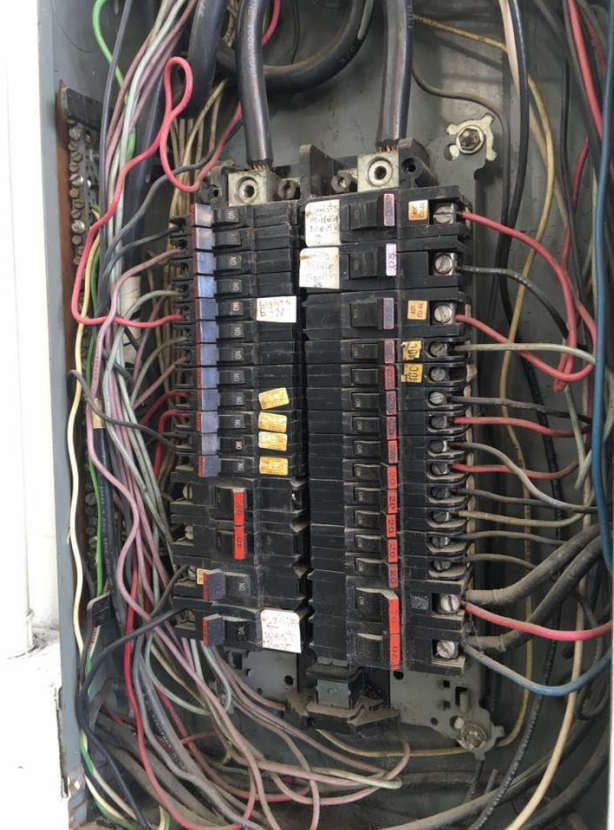

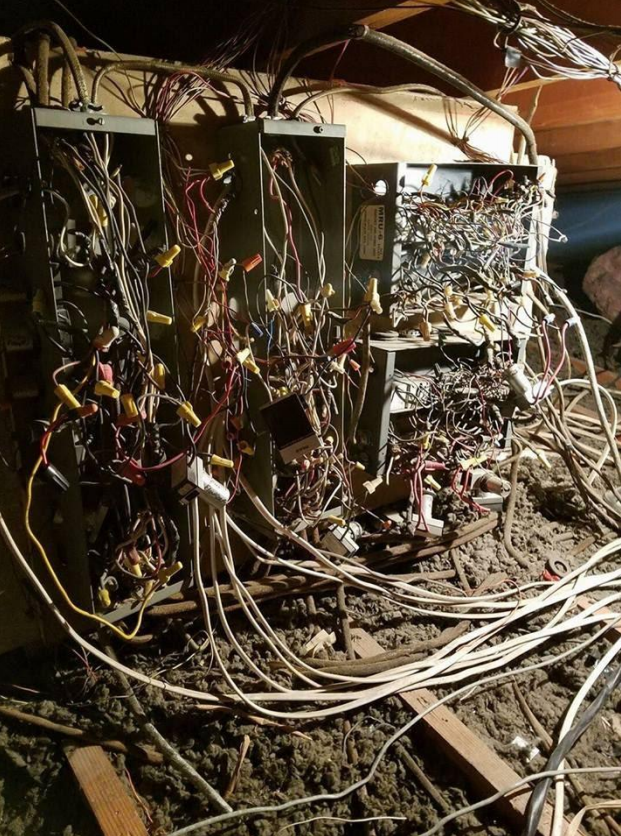

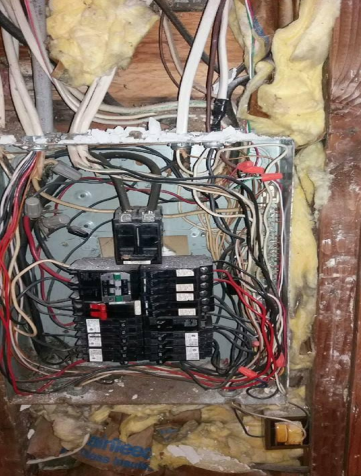

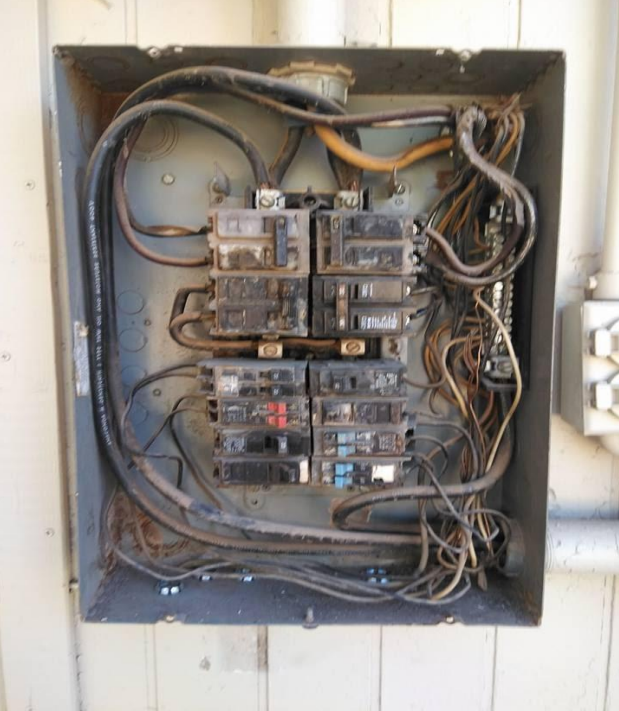

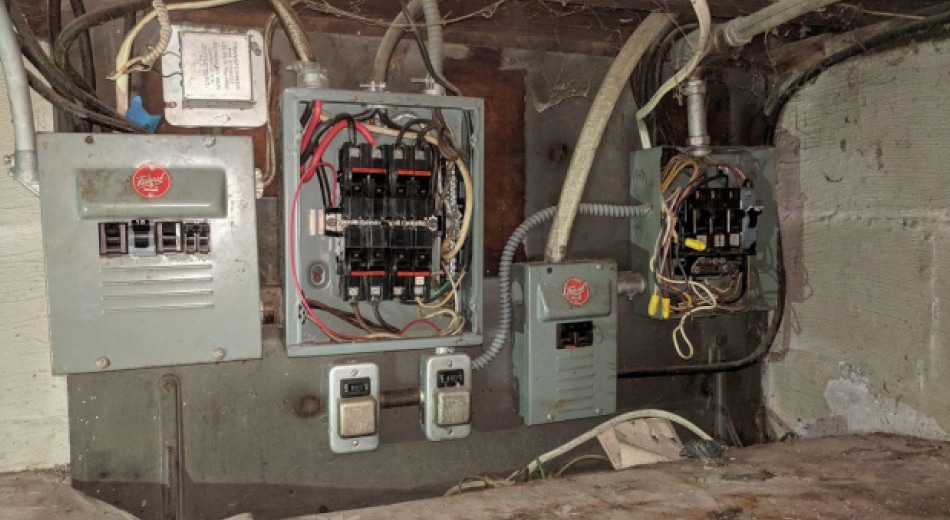

25 of the Worst Electrical Panels We’ve Ever Seen

August 15, 2022

We’ve all seen them at least a few times throughout our careers and sometimes on a weekly and daily basis. They are chaotic, illegal, illegible and downright dangerous electrical panels that unfortunately still exist in the walls of homes, commercial buildings, hospitals, and schools. They have messy writing, scrawled notes, faded numbering, and impossible tangles of wires (so many wires!) – we’ve seen it all. Here are the 25 worst and most dangerous electrical panels we’ve come across to date.

CriticalAsset eliminates the hassles of facilities asset management, allowing you to effortlessly manage and track all your infrastructure assets and devices in one place, saving you time and money. Sign up for a free trial.